Time is money and speed is the king. This trend does not stop at turnarounds – but does it allow optimizing the performance of turnarounds?

Turnaround benchmarking challenges

Benchmarking helps measure the best practice in turnarounds and is part of a continuous improvement process that incorporates feedback to your next turnaround. It targets roles, processes, and critical success factors. Roles are what helps in defining the turnaround functions. Processes are what consume a company’s resources. Critical success factors help gain a competitive advantage in the long-term.

Reliable and relevant benchmark data is becoming more and more important when estimating the cost of turnarounds, executing proper cost control, and forecasting turnaround budget in the long-term. However, project data is often not stored in a centralized database and scattered all over the place in Excel files, which is like a brick wall that is too high to climb over to reach success.

You can use industry-standard labor norms and costs to compile a complete cost dataset. However, every site has its unique aspects, which you should take into consideration when creating an estimate using the industry-standard data. You would want to know which costs apply to your specific plant or refinery. If you want to continue where you left off in your last TA, your 10% estimate/baseline in combination with the benchmark outcomes will constitute the basis for your new TA. Another challenge is the continuous pressure to get the TA (Turnaround) completed as soon as possible. The project team is assembled quite sometime before the actual TA execution but sent away as soon as the TA is finished.

This leaves no time for a quality close-up to analyze the data and discuss the lessons learned. Without learning from the experience, how can you improve something? Such speed has a major impact on the overall benchmarking process.

Why you need turnaround benchmarking

Benchmarking is all about learning from previous experiences, extracting metrics from the TAs, discovering trends in key cost drivers and ratios, comparing the performance of projects and common assets, and improving the accuracy and reliability of the future cost estimates. Now, let’s look at some of the key benefits you will get from turnaround benchmarking:

- Benchmarking allows you to capture and collect meaningful project information from executed and ongoing projects. From high-level data such as mechanical hours vs total cost to more detailed equipment-specific data such as the average cleaning hours needed per exchanger.

- It enables the improvement of accuracy and reliability for your future turnaround cost estimates.

- Benchmarking increases the efficiency of utilising the past data, especially when working with a new turnaround team every time.

- It allows the organization to assess where it stands competitively against various measures, including industry best practices that lead to superior turnaround performance.

- Benchmarking helps overcome the challenges in your next turnarounds by revealing the information like what went well the last time, where the budget exceed expectations.

Summary

It is quite obvious now that not only the operation but also the revision of many large-scale plants are under huge profitability pressure. Due to the substantial amounts of outstanding work and delays, many industries are facing cost overruns. Hence, to achieve an optimised turnaround cost level, it is very critical to implement benchmarking and compare your shutdown and turnaround performances.

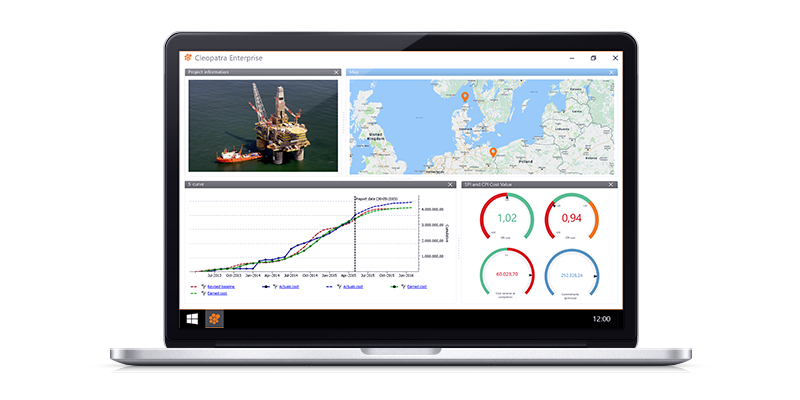

Cleopatra Enterprise Team is helping companies operating globally with these kinds of turnaround challenges every day. Learning and improving continuously is the only way to lead in this digital era. To improve the quality of your TA Cleopatra Enterprise efforts in the future; ‘Close the loop‘ and ‘Use the experiences from the past’.

Turnaround Benchmarking

Cleopatra Enterprise Software

Cleopatra Enterprise extracts metrics from executed and running STOs and improves your future turnarounds.