With hundreds or even thousands of work orders consisting of multiple activities, the complexity of planning and scheduling increases drastically for an STO. An extraordinary skillset is required to create a turnaround schedule that is optimized for cost, technically smart, and idealized in duration.

One of the turnaround experts of Cleopatra Enterprise has been helping process industries in achieving smooth turnaround and shutdown management which means leaving no room for schedule delays and cost overruns. His recent experience was with turnaround cost controlling and scheduling for a client who is a frontrunner in the chemical industry.

We have asked our expert 3 core questions to get the key insights on the challenges faced during turnaround scheduling.

Based on your experience, could you share some tips with turnaround professionals on how to optimize turnaround scheduling?

1. Collect all task information (work-packages) for the schedule from all different disciplines (E&I, Mechanical, SIP, etc.) and continuously check with work preparation if the data is correct. Everyone makes mistakes and continuous feedback loops can help to avoid this.

2. Define clear tasks in the turnaround work packages with the right amount of information. The schedule often tends to be too detailed or too high level. Too detailed schedule leads to a TA that is uncontrollable, while too high-level one leads to a vague work description.

3. Baseline the turnaround project at a work package level rather than at the individual activity level. When all individual work packages are scheduled it is difficult to have a helicopter view of everything.

4. Try to find uniformity of the turnaround cost data. Since the preparation of the work packages is managed by different employees, the data may not be consistent.

5. Look for the right balance between conflicting interests such as efficiency vs. levelling.

6. Draw insights about the relationships between different activities such as activities from different work packs where the activity of one work pack influences the activity of another work pack. E.g. the repair of a mixer (separate work pack) which is inside a tank that must be cleaned (the other work pack).

Can you provide us with 3 examples of typical mistakes and their solutions?

1. In most of the cases, a turnaround schedule is not 100% accurate. Therefore, it is important to stay in touch with all stakeholders and explain the schedule. What are the starting points? What is included and what is excluded?

2. In various cases, the labour norms are not entered consistently in the work packages. The solution is to incorporate a labour norms dataset in the system that helps with the consistency of the data.

3. Progress reporting is sometimes misinterpreted, which led to various discussions. To solve this partly split the report in reports per operational unit instead of 1 total report for the whole event and partly adjust the schedule during execution for some of the errors which were in there.

What is your golden rule of scheduling?

I don’t have one but three.

Rule 1: Always strive for 100% accurate schedule but know and accept the fact that it’s difficult to achieve such accurate scheduling. The ultimate goal is to achieve the best execution but not perfect planning.

Rule 2: As a scheduler, you have to deal with many parties in the project such as the Management, Work Preparation, Execution, and Contractors. Communication with all these parties is essential. What do you need from whom and who do you need to inform again?

Rule 3: Ensure that the correct structures such as the operational systems, phases, and locations of the turnaround project are in place. This constitutes the basis of a clear, well-defined schedule.

Turnaround Scheduling

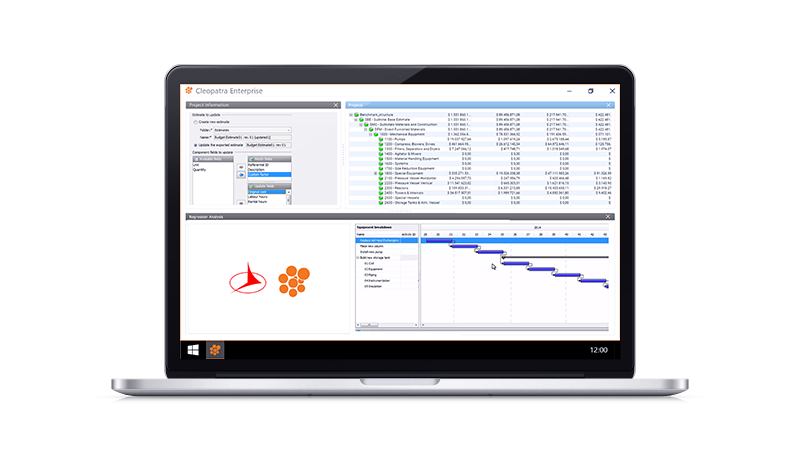

Cleopatra Enterprise Software

With Cleopatra, develop an optimized schedule that minimizes the out-of-service cost with maximum resource usage.