In the early phases of projects within the Tank Terminal industry, you may not have all the details ready to estimate your costs. Yet, you need to make estimations for critical things like project screening, determination of feasibility, concept evaluation, and preliminary budget approval.

Fortunately, with limited information, you’re still able to make estimations based on two methods: factorized estimating and quantitative estimating.

Method 1: Factorized estimating

With factorized estimating, the methodology starts with estimating the equipment costs. This is the only input needed. Once you have that in place, you can derive the Total Installed Costs (TIC) by multiplying the equipment costs by so-called TIC factors.

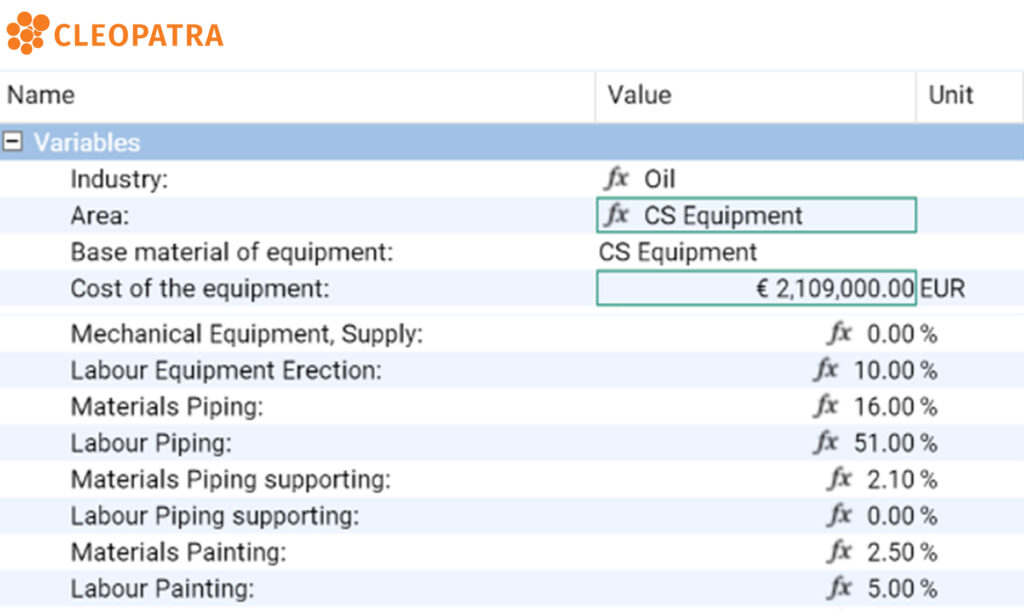

In Cleopatra Enterprise, the cost estimating software tool, TIC factors are also used.

How we typically start these estimates is by estimating the equipment costs by our in-house developed equipment cost models. These cost models provide the equipment costs based on a certain number of input parameters. For instance, the capacity of a pump, the dimensions of a tank, or the material for the construction of the different equipment.

The second step is multiplying the equipment cost with the TIC factors, which we developed in-house and benchmarked them against historical project data.

It’s important to consider that every industry has its unique engineering principles and project development.

For instance, within tank terminal projects, the tanks are a big portion of the total project cost. Therefore, it’s crucial to check the type of project and determine if the factors are valid for estimating. In addition, factors are not applicable to all of the components in a tank terminal. Estimators should look at their historical data in order to create these factors, so a realistic number for their total project cost can be derived.

Cleopatra Enterprise: Input field for factorized estimating

Advantages

- Limited engineering input required

- Quick results

- The relatively inexpensive estimating method

Disadvantages

- Wide accuracy range

- Quantities can not be checked: only input and output

- Limited possibilities for adjustments

- Estimating with only historical data

- Labor-intensive to develop benchmarks with a similar basis

Method 2: Quantitative estimating

In a quantitative estimate, we look at components that are expressed in the units of measurements. For instance, length in the pipe, cubic meters of concrete for foundations, and installation hours.

By multiplying these quantities for the components with a unit cost, you can derive your estimated cost. Although this sounds similar to a detailed approach, it’s still an early phase estimate in which you don’t have detailed information yet.

All the quantities that are used in this method are based on assumptions, predicted on historical data and experience. No discipline Material Take-off Lists (MTO) or Bill of Quantities (BOQ) are available and used to generate quantities. Therefore, the equipment list is still a starting point and from there the quantities are derived.

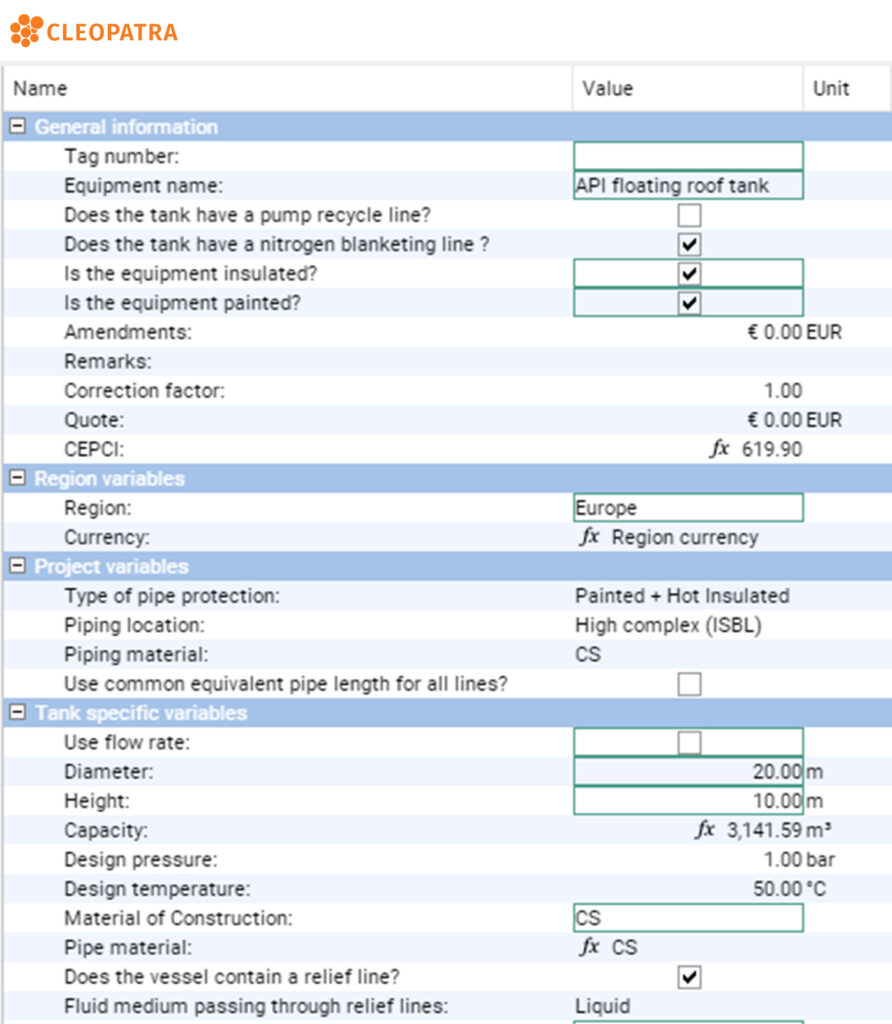

In Cleopatra, we also use quantitative estimating. In order to derive an estimate, some details are needed. However, Cleopatra offers default values that can be used when not all information is available yet, which is common in early phase estimating. The cost model calculates the Supply and Install Costs of the tank based on their input. Our models use standard P&ID’s in order to derive quantities and typical items that are connected to the tank.

In the tank terminal industry, some specific equipment is needed, such as marine loading arms. We approach this by using historical project data or we request a budget quote from the market. Since these are quite specific items that can have specific costs, it always helps to get some additional cost data.

Cleopatra Enterprise: Input field for quantitative estimating

Advantages

- More accurate estimate

- Quantities are more or less fixed units per project, which can be used year after year

- Quantities are not influenced by inflation, currency fluctuation, and other economical factors

- Improves insight and communication

Disadvantages

- More complex and time-consuming compared to Factored Estimating

- An extensive unit-rate cost database should be developed and maintained

Conclusion

All in all, both methods allow you to make estimates with limited information. And this is very valuable at an early stage of a tank terminal project. Factorized estimating is a less complex and quicker method compared to quantitative estimating. However, quantitative estimating may be the right method for you if you have a well-maintained cost database to develop this kind of estimate and experienced estimators with time to check them.

Do you want to know which estimating method suits your project best, or how Cleopatra Enterprise can help you better your project performance? Please feel free to contact us.

Estimating & Budgeting

Cleopatra Enterprise Software

Define your budget accurately with Cleopatra Enterprise to predict cost, time, and resources. Form the basis of project control.

Digital Shutdown & Turnaround Management: How Integration improves TA performance

On-demand Webinar

During this webinar, you will discover how a digital system that combines functionalities for scope management, work package management, scheduling, estimating, cost control and benchmarking serves as a powerful tool to transform shutdown and turnaround processes.